Thanks for your follow up!

I’ve been busy lately and i made some improvement! I have to confess that I went back on my main idea which was to “not” weld/modify the RaspberryPi circuit. I managed to convert the 3d file (.stl) to a FreeCad format but i have a polygon that poped and i cannot found how to get rid of it(learning curve issue).

So i decided to keep the standard case mesurement and try my best to stuff everything inside.

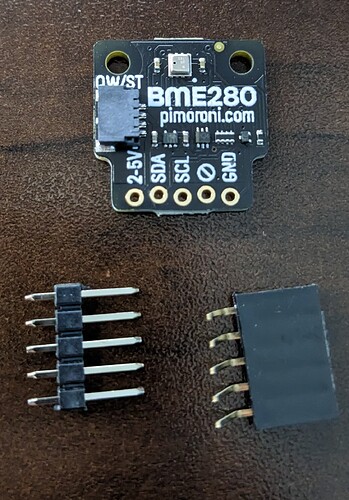

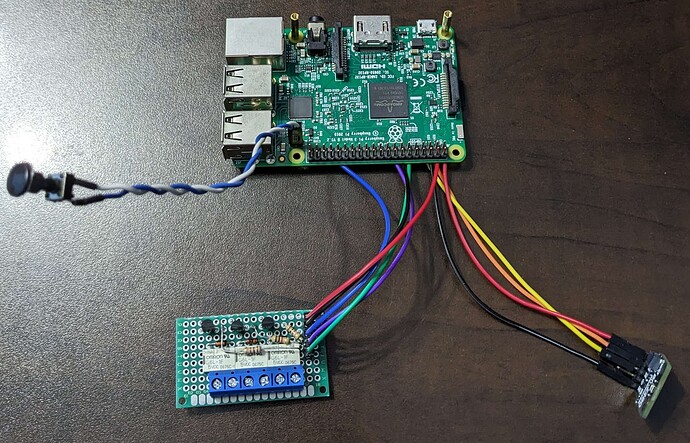

It went pretty good as my friend gave me a hand with the custom circuit board required to run the relays.

Long story ahead

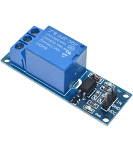

That part is important for anyone who’s willing to rework the way this projet behave, for exemple having to use DC Relay instead of AC SSR(Solid State relay). Both relay operation dont have the same effect on the RPI Board. Keep in mind that the total output for all GPIO is 50ma and each pins are 18ma for pullup. The SSR is a “contact less” relay so the input is isolated and require few ma to operate. The DC relay wich is mecanical have some caracteristic that can be chalenging. The input require more power and the fact that it use a coil, that can create a “bounce back” on the GPIO pin wich can “toast” the board(or the GPIO).

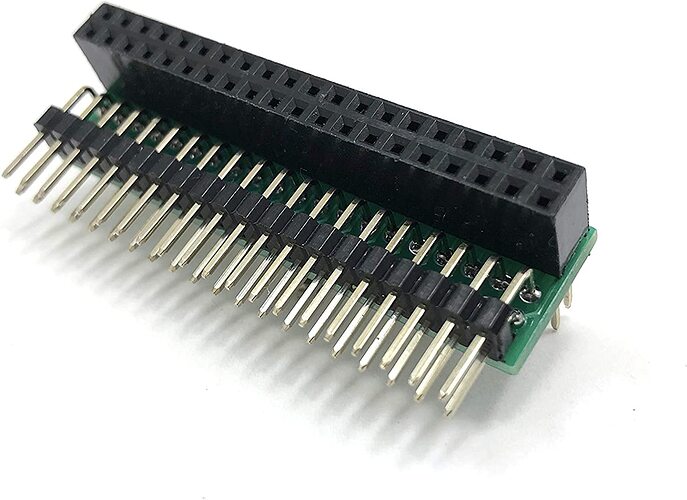

So with that in my we needed to boost the output of the GPIO and create electronic isolation between the relay and GPIO.

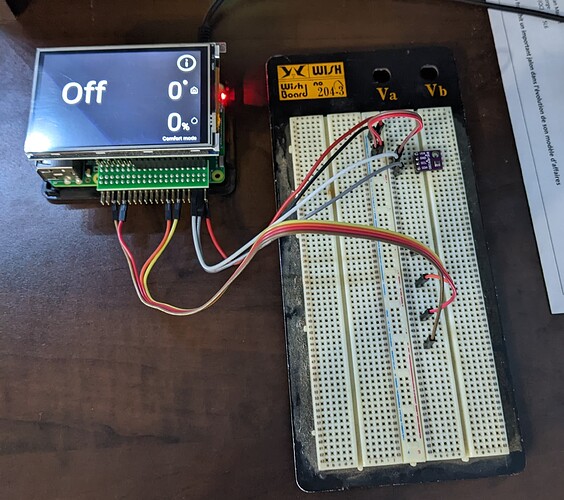

This was done using somes transistors/resistors/diodes and a little project board. Its not as pretty as a factory made board but it works! (see picture below).

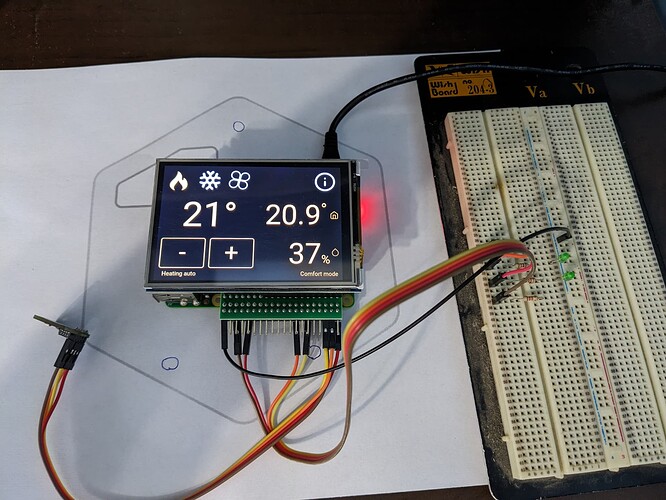

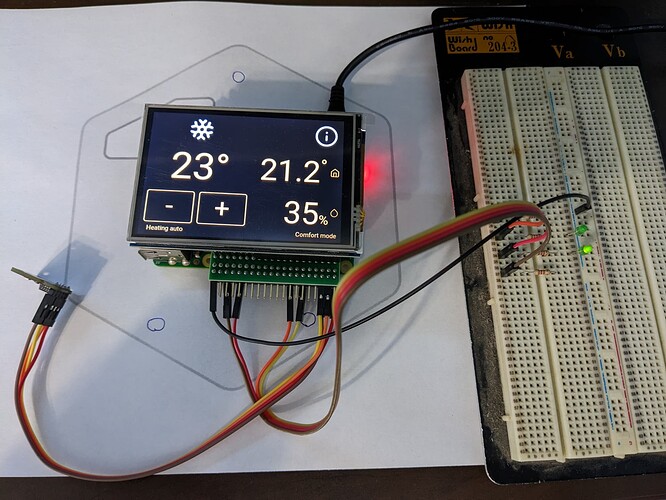

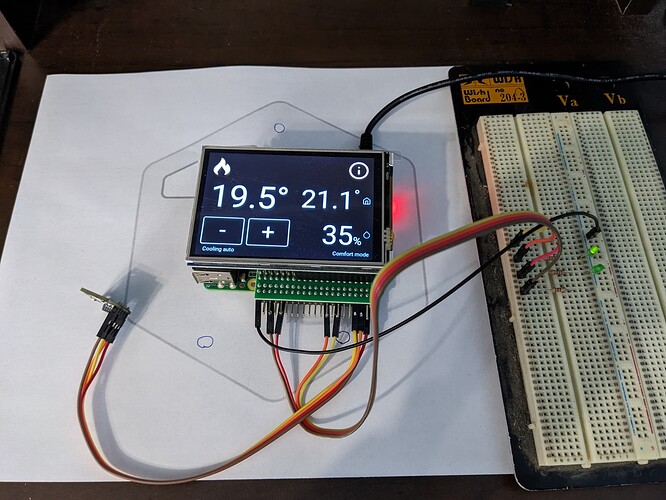

So after all of this i have a fully working Hestiapi thermostat running on Rasbperry Pi3b+.

But i have two issues to solve:

1-The LCD screen i’m using is upside down. I have to find how to manage this from the software or OS side. It use same XPT2046 controler so the SDK should be also the same as the original one. *If someone have a clue let me know plz

2-I cannot screw the PI on the backplate so everything is holding to the screen and the three little tabs that hold it in place. I already craked one while inserting the screen. I might have to reenforce them with glue or find a way to fix the Freecad file and alter the design.

Sorry for writing my whole story, i make this so it can stimulate other to do some DIY.

Here are my pictures of the project so far!

Edit: I managed to make it work! But then the touch i started acting backward:

I fliped the display by adding dtoverlay=waveshare32b:rotate=270 in /boot/config.txt but the touch remaned backward. I wasn’t able to lunch “xinput_calibrator” due to an error and i ended up crashing my PI Image. So i re-image the SD card then this time i followed the procedure used when you do a manual installation but only the LCD part:

https://github.com/HestiaPi/hestia-touch-openhab/wiki/Manual-Installation-ONE#lcd-start

Blockquote LCD START

wget http://www.hestiapi.com/download/LCD-show-170703.tar.gz \

&& tar xvf LCD-show-170703.tar.gz \

&& cd LCD-show/ \

&& sudo ./LCD35-show;

Pi reboots with LCD working and stops at console prompt.

sudo rm -rf /home/pi/LCD-show LCD-show-170703.tar.gz;

sudo dpkg -i ./LCD-show/xinput-calibrator_0.7.5-1_armhf.deb \

&& sudo rm -rf LCD-show* \

&& sudo mkdir /etc/X11/xorg.conf.d \

&& sudo touch /etc/X11/xorg.conf.d/99-calibration.conf \

&& echo 'Section "InputClass"

Identifier "calibration"

MatchProduct "ADS7846 Touchscreen"

Option "Calibration" "3900 218 246 3832"

EndSection' | sudo tee /etc/X11/xorg.conf.d/99-calibration.conf;

sudo DISPLAY=:0.0 xinput_calibrator

I dont understand why it i have to re-run the calibrator after each reboot.

I guess i need to set something to make this permanent?

Regards

Christian

![]()