I did some testing with the pin lengths to try to find the shortest mating length that would still be long enough to make contact with the LCD panel.

First, some terminology:

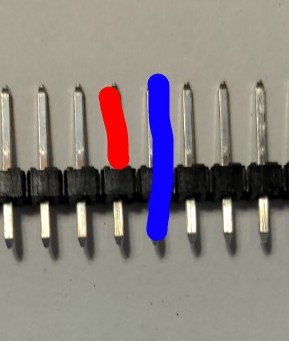

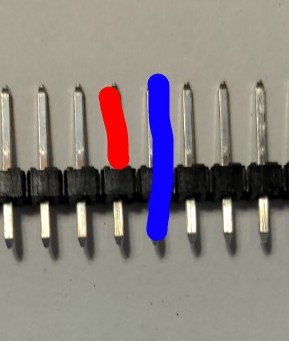

In the image above, the red line is attempting to show the mating length. That is, the length from where the pin comes out of the plastic to the tip.

The blue line is attempting to show the pin length. That’s the entire pin.

In case you are wondering, the term for the bottom segment is the pin tail length. That is from where the pin comes out of the plastic on the bottom to the bottom tip.

With that out of the way, in our case, the important value is the pin length, as that is what could be attempting to hold the case apart, putting pressure on the touchscreen, and causing it to not respond to taps.

I was able to confirm the a pin length of 12mm and a mating length of about 7.5mm still functions.

It also worked for me with what must have had a total pin length of 14.5mm because I measured the mating length and it was 10mm. That is, it fit in the case, the screen showed the UI and the touchscreen worked.

I measured the length of the long headers that I have not installed yet and it’s a 17.5mm pin length and a 12mm mating length. I’ve had to switch manufacturers a couple times due to supply chain issues though, so it’d be worth measuring to confirm you have the exact same measurements on your side.

In case you don’t have calipers, a US nickel is almost exactly 2mm thick. So if you chop two nickels’ worth off the top of your pins, you should be good to go.

On the next unit that I assemble, I’ll try testing it without trimming the tails to see if I can reproduce this issue. If I can, I’ll try to do additional tests with cutting things down to size.

Once we get this sorted out, I’ll make sure to trim all the parts down to size until I can source ones that are shorter, but not too short!